Product +

Continuous casting and rolling production line

- Rolling direction: Vertical series

- Capacity: Above 3T/H

- Rolling speed: At least 5m/s

- Size of billet: 40*40-120*120

- Dimensions of final product: 6-16mm

Video:

Application:

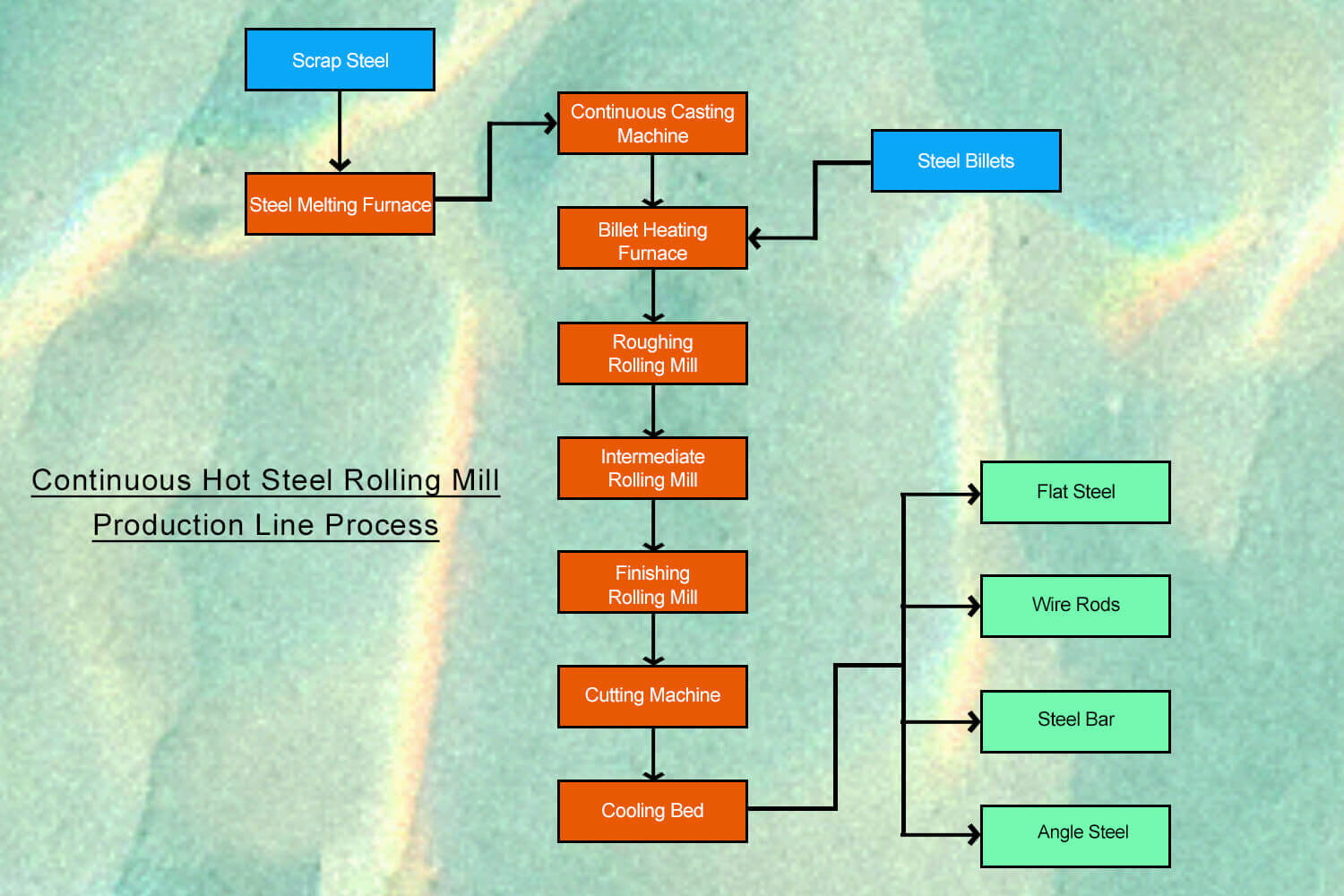

The continuous steel hot rolling mill is an advanced steel rolling production line. The steel billet from the continuous casting machine or pre-heated by the billet heating furnace is rolled in several stands at the same time, and rolling along the same direction finally forms a certain section shape. It applies to most of steel plants to produce section bars, wire rods, steel bars, channel steel, flat bars, steel plates, and other products.

[caption id="attachment_2263" align="alignnone" width="1500"] HTGP Continuous Hot Steel Rolling Production Line Process[/caption]

HTGP Continuous Hot Steel Rolling Production Line Process[/caption] Product Features:

- 1. The raw material is steel scrap or billet (40-120mm). The production capacity is suitable for 5- 20t/h, and the diameter of the steel bar of the final product is 6.5-32mm.

- 2. Save energy consumption by using continuous casting billets.

- 3. Save the metal consumption and improve the metal forming.

- 4. Simplify the production process, reduce plant area and transport equipment, and save infrastructure investment and production costs.

- 5. Greatly shorten the production cycle.

- 6. Provide overall solution and after-sales guarantee.

- 7. Provide plant design, proposal, manufacturing, shipping, installation, and commissioning services.

- 8. Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout, and other services.

Specification:

| Specification and Technical Parameter |

||||

| Capacity(T/Hour) |

Working hours(Year) |

Electricity consumption |

Feed section |

Rebar diameter |

| 5 |

2400 |

5MW |

60*60 |

Ø8-16 |

| 8 |

2400 |

8.5MW |

70*70 |

Ø8-16 |

| 10 |

3600 |

9.5MW |

90*90 |

Ø8-32 |

| 15 |

3600 |

10MW |

120*120 |

Ø8-32 |

| 16 |

6000 |

15MW |

120*120 |

Ø6.5-32 |

| 35 |

6000 |

26MW |

150*150 |

Ø6.5-32 |