Product +

Induction heating furnace

- Heating type: MF Induction

- Heatable material: Gear bearings, pipe, rod, steel bars, locally heated U-bolts

- Heating temperature: 200-1300 degrees

- Heating speed: According to the request

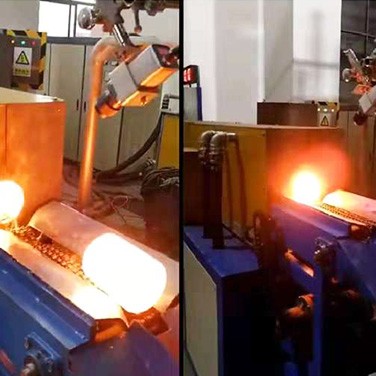

Video:

Application:

The billet induction heating furnace is mainly used for workpiece heating in the continuous casting and rolling production line. The heating temperature is between 200-1,400 degrees.

1. Pre-forging heating: applied to gear, ring gear, bearing, shackle, and rigging.

2. Online heating: Pipe anti-corrosion coating, long steel rod heating, steel (wire) tube online quenching, and tempering.

3. Local heating: U-bolt bending, thermal assembly of the drum, steel pipe elbow, etc.

Product Features:

- 1. The induction coil is insulated by two insulation treatments, high-temperature insulating paint and fiberglass ribbon winding.

- 2. The top of the furnace body is designed with a sliding cover, which is convenient for maintenance and inspection.

- 3. Equipment installation and operation is simple.

- 4. Equipment covers a small area

- 5. Stable and reliable heating temperature

- 6. Power consumption 280kwh/ton

Specification:

| Specification and Technical Parameter |

||||

| Model |

MF Power |

Input Voltage |

DC Current |

MF Frequency |

| GTR-200 |

200kw |

3ph, 380V |

400A |

2-10KHZ |

| GTR-300 |

300kw |

3ph, 380V |

600A |

2-10KHZ |

| GTR-400 |

400kw |

3ph, 380V |

800A |

2-10KHZ |

| GTR-500 |

500kw |

3ph, 380V |

1000A |

2-10KHZ |

| GTR-800 |

800kw |

3ph, 380V |

1600A |

2-10KHZ |

| GTR-1000 |

1000kw |

3ph, 380V |

2000A |

2-10KHZ |

| GTR-1500 |

1500kw |

3ph, 380V |

3000A |

2-10KHZ |

| GTR-2000 |

2000kw |

3ph, 380V |

4000A |

2-10KHZ |