Product +

Induction Drying Furnace

-

- Model: HT2-14500 Brand:HTGP

- Size: Height 1500mm-Width 2300mm-Depth 3500mm

- Supply voltage comes from AC mains: 〜380V

- AC frequency: 50Hz

- Furnace expected power: 52 kW ± 5%

Video:

Application:

- The induction drying furnace is designed for drying and heating various equipment, including electric motors in air at temperatures up to 100°C under stationary conditions by the method of losses due to magnetization of the steel of the furnace walls.

- The furnace has a climatic design UHL, location category 4 according to GOST 15150-69, ambient temperature from +5 to +35gr.S.

- Relative humidity of the environment is not higher than 80% at a temperature of +20°C, atmospheric pressure is from 84 to 106 kPa.

Product Features:

-

Design Features:

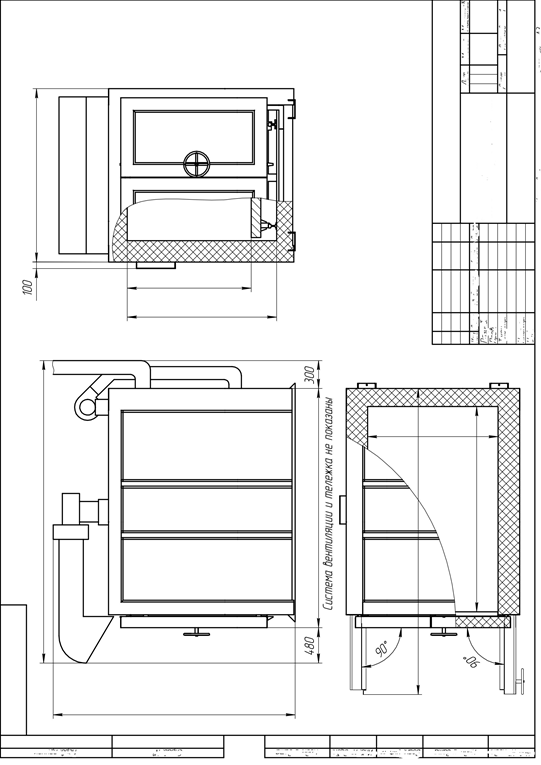

- Furnace space layout: horizontal

- Door design: hinge

- Door drive type: Manual

- Availability of mechanized trolley drive: Yes

- Whether separate power measurement is required: No

- The nature of the placement of the product on the loading device, with a sketch of the loading device (pallets, racks, baskets, racks, muffles, etc.) using crane beams The colors of panels and strips comply with the RAL color lines (standard version - gray): Design example: gray

- The working space of the furnace is an octagonal enclosed chamber with a hinged door. The furnace body is placed horizontally.

- The oven is equipped with a ventilation system consisting of a fan exhaust recirculation loop connected to an "umbrella" ventilation box above the door.

- A recirculating exhaust loop provides constant convection within the furnace to achieve temperature uniformity throughout the workspace, with hot air drawn from the upper portion of the furnace and injected into the lower portion of the furnace through ventilation ducts along the side walls. Air flow between exhaust and recirculation.

- The amount of air passing through the oven is controlled at the outlet of the oven.

- The fan is connected to the duct through the opening of the damper, which has a ventilation "umbrella" above it Designed to vent gases from the furnace when the door is open. Automatically opens when the door is opened and automatically closes when the door is closed.

- The air inside the oven is heated by induction through the metal (steel) walls of the oven. The furnace walls are heated due to magnetization losses in the three-phase copper windings connected to the grid. The three-phase winding is wound on the outer wall of the furnace

- heat insulation. The winding is made of insulated copper wire, and the ends of the winding are connected to the terminals in phases as the head end and end end of the winding.

- The working temperature sensor and emergency temperature sensor are installed at the rear of the furnace body. When the set temperature is exceeded, an alarm is triggered and the furnace is shut down. The furnace is equipped with a device to disconnect the power supply to the induction winding and When the door is open, turn on the exhaust fan located above the door.

- Automation equipment allows you to automatically select the best operating mode of the induction winding, thus providing the lowest power consumption and the fewest starts to reduce the number of starts and avoid transient operating modes.

Specification:

-

Equipment specifications:

- Maximum heating temperature - 100 gr.С;

- Drying (heating) temperature - 50-100 gr.С;

- Type of heaters - copper winding;

- Emergency shutdown temperature - 110gr.С;

- Uniformity of temperature distribution - ± 5 gr.С;

- Supply voltage from AC mains ~ 380V;

- AC frequency - 50Hz;

- Number of phases - 3;

- Estimated power of the furnace - 52 kW ± 5%;

- Estimated average power consumption of the furnace - 22 kW ± 5%;

- The maximum mass of loaded products - 7400kg.

- height - 1500mm (from the supporting surface of the trolley to the ceiling of the working chamber);

- width - 2300mm;

- depth - 3500mm.

- Delivery set:

- Drying electric oven - 1 pc.;

- Electric power cabinet - 1 pc.;

- Electric control cabinet - 1 piece;

- Trolley - 1 piece;

- Ventilation box "umbrella" - 1 piece;

- A set of cable products (at least 10m) - 1 pc.

-

The system allows:

- - regulation of the temperature process according to a given program, as well as in manual mode; - select current temperature readings on the screen; - select the graph of the temperature process for the entire period of the drying process;

- - archive and view process data for at least 30 days;

- - upload archived data to external electronic media (flash cards).

-

Furnace control system:

Do you need to save and view information: Yes Whether to provide a touch screen to control the process: Yes Availability of monitoring system with remote control access: No