About induction furnace: preheating method and precautions

When the induction furnace is working, it is easy to cause accidents such as splashing due to the presence of moisture on the crucible wall, burying hidden dangers for the personal safety of operators. How to avoid similar dangers from happening? A very common practice is to preheat, and today we will give you a brief introduction.

The first is the preheating process.

1. When using an induction furnace, preheat the crucible to about 200°C for 30 minutes without adding material, and dry it for 60 minutes. This is to allow the surface moisture of the crucible to volatilize and prevent bursting in the initial stage of use.

2. After preheating, the crucible should be heated to 900℃-1000℃ (about 2 hours) as soon as possible, keep the temperature for 20-30 minutes, and then return to the temperature when the metal needs to be smelted. This is done so that the crucible can quickly pass through temperature areas prone to oxidation.

3. After each preheating, it is only necessary to keep the electric furnace running. Unless the furnace is stopped or the crucible is damped again, there is no need to preheat again.

There are also some inspection notes.

1. Carefully check the bottom and inner wall of the crucible. If any dents and cracks are found, they should be repaired in time.

2. Check the furnace top, furnace nozzle and furnace cover. If sand loss and looseness are found, pay attention to trimming and tightening.

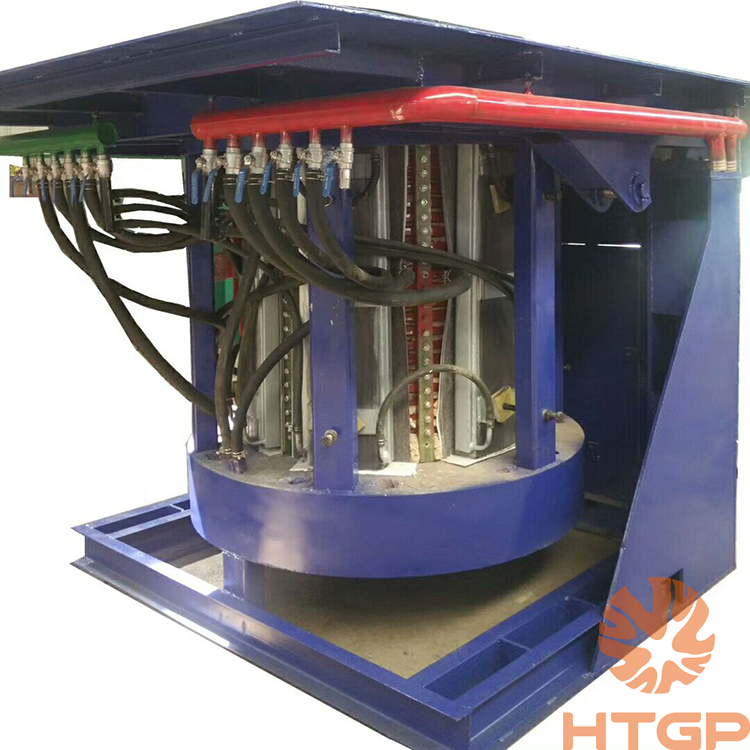

3. Check the induction coil. If iron filings and other debris are found on it, remove it immediately.

4. Check the connection bolts between the induction coil and the insulating column. If they are found to be loose and fall off, they should be filled up and tightened in time.

5. Check the entire water-cooled circulation system, focusing on the water-cooled cable, to ensure that the water supply is smooth and there is no leakage.

6. Check the mechanical operation of the furnace body overturning, which is very important for safe production. If any fault is found, remove it in time.

This is the knowledge about induction furnace preheating. Many companies do not pay attention to these details during the production of electric furnaces, which will cause some production accidents. Hope our summary today can help you.

The induction furnaces produced by Luoyang Hongteng have good heat permeability, uniform temperature, and are very convenient to install and operate. Welcome to follow us and let us solve more problems about induction furnaces for you.

Welcome to follow us Luoyang Hongteng to help you learn more about melting furnaces.

Video of the use process of the melting furnace