HighEfficiency Aluminum Melting Machine | Industrial Furnace Solutions

Aluminum Melting Machine: A Key Component in Modern Metal Processing

Aluminum has become one of the most widely used metals in the world, thanks to its lightweight, corrosionresistant, and highly conductive properties. From automotive parts and aerospace components to packaging and electronics, the demand for highquality aluminum products continues to grow. At the core of aluminum processing is the aluminum melting machine—a critical piece of equipment that enables manufacturers to transform raw aluminum or scrap into molten metal for casting, alloying, or recycling.

1. What Is an Aluminum Melting Machine?

An aluminum melting machine is a type of industrial furnace designed to heat and melt aluminum materials. It can handle a wide range of inputs, including virgin ingots, recycled aluminum, and aluminum alloy scraps. These machines operate at high temperatures (typically 660°C or above) and are used in metal foundries, casting factories, and recycling plants. The most common types of aluminum melting machines include induction furnaces, crucible furnaces, and rotary furnaces.

2. Main Types of Aluminum Melting Furnaces

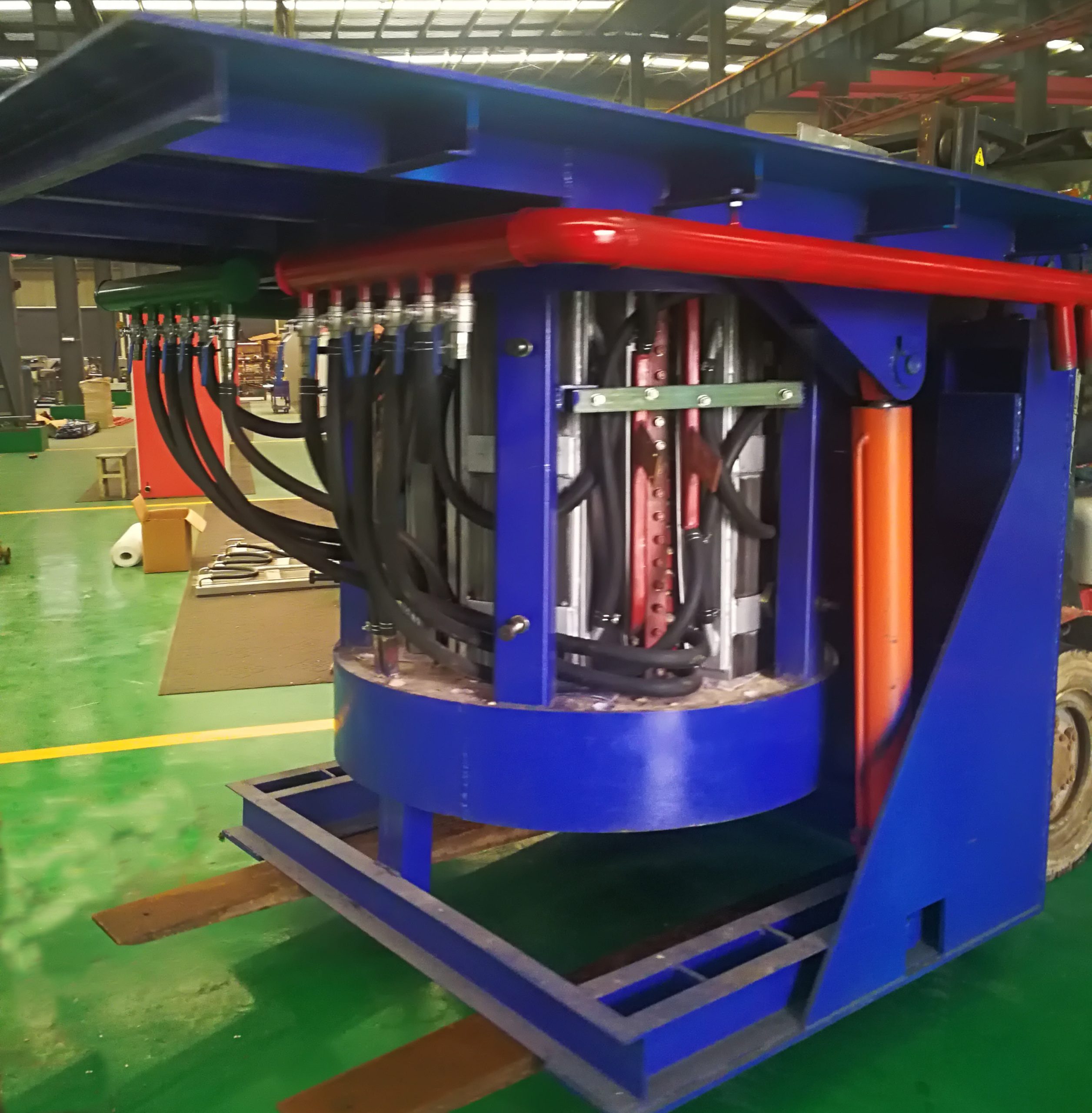

Induction Melting Furnace

Induction furnaces use electromagnetic induction to generate heat. They offer precise temperature control, low energy loss, and clean melting environments, making them ideal for highpurity aluminum applications.

Crucible Furnace

This type involves placing aluminum inside a ceramic or graphite crucible, which is then heated using gas or electricity. Crucible furnaces are widely used in small to mediumscale foundries due to their simplicity and costeffectiveness.

Rotary Furnace

Rotary furnaces are typically used in aluminum recycling operations. They offer high melting efficiency and can handle contaminated scrap with fluxing agents to remove impurities.

3. Key Features of a Modern Aluminum Melting Machine

Fast Melting Speed: Advanced burners and induction systems reduce melting time, increasing productivity.

Energy Efficiency: High insulation and smart temperature control minimize energy loss, saving operational costs.

Automated Operation: PLC (Programmable Logic Controller) systems ensure safe, handsfree operation with realtime monitoring.

Temperature Control: Digital controllers help maintain precise temperatures during the entire melting cycle.

Safety Systems: Overheat alarms, emergency shutdowns, and tiltpouring mechanisms enhance operator safety.

4. Applications of Aluminum Melting Machines

Aluminum melting machines are widely used in various industries, including:

Automotive Industry: Melting and casting of aluminum engine blocks, wheels, transmission housings.

Aerospace Sector: Precision melting for highstrength aluminum alloys used in aircraft frames.

Recycling Plants: Processing of aluminum scrap into reusable molten metal for further fabrication.

Packaging Industry: Melting aluminum for products like cans, foils, and containers.

Die Casting and Foundries: Used for preparing molten aluminum to feed into casting molds.

5. Choosing the Right Aluminum Melting Machine

When selecting an aluminum melting machine, several factors must be considered:

Production Capacity: Determine how many kilograms or tons of aluminum you need to melt per batch or per hour.

Fuel Type: Options include electric (induction), natural gas, diesel, or hybrid systems.

Automation Requirements: Decide if your operation requires fully automated systems with remote monitoring.

Furnace Design: Vertical or tilting type, fixed or mobile, depending on your facility layout and workflow.

AfterSales Support: Choose a manufacturer that offers installation, training, maintenance, and spare parts.

6. Environmental and Economic Benefits

Modern aluminum melting machines contribute to sustainable production by:

Reducing Energy Use: Advanced insulation and efficient heat transfer lower overall energy consumption.

Minimizing Emissions: Cleaner combustion and emission control systems help meet environmental regulations.

Recycling Capability: Ability to melt scrap aluminum reduces reliance on primary aluminum production, cutting costs and carbon footprint.

7. Future Trends in Aluminum Melting Technology

The aluminum industry is moving toward more digitally integrated, energyefficient, and environmentally responsible operations. Innovations include:

IoTEnabled Furnaces: Realtime data collection for predictive maintenance and operational optimization.

Hybrid Energy Systems: Combining renewable energy sources with conventional fuels to lower emissions.

Advanced Alloy Processing: Machines designed for precision melting of aluminum alloys used in hightech industries.

Conclusion

An aluminum melting machine is an essential investment for any facility involved in aluminum casting, fabrication, or recycling. The right equipment can enhance product quality, improve energy efficiency, and reduce operating costs. Whether you operate a small foundry or a largescale aluminum processing plant, choosing the right type of melting furnace is key to staying competitive in today’s fastevolving industrial landscape.

When sourcing an aluminum melting machine, work with experienced manufacturers who offer customized solutions, technical support, and proven durability. With the right technology in place, your business can meet production demands while embracing cost savings and sustainability.

HighPerformance Copper Smelting Equipment | Reliable Furnace Solutions

1T Resistance Aluminum Melting Furnace for Sale | HighEfficiency Industrial Furnace

HighQuality Rebar Mill for Sale | Steel Bar Rolling Mill Manufacturer