How to Improve the Melting Efficiency of Medium Frequency Induction Furnace?

The melting efficiency of a medium frequency induction furnace is vital to a foundry. If you want to improve the melting efficiency of the medium frequency furnace, please read this article thoroughly.

In this article, we will tell you four things about the medium frequency induction furnace, including:

- 1. How does a medium frequency induction furnace work?

- 2. What affect the melting efficiency of a Medium Frequency Induction Furnace?

- 3. How to improve the melting efficiency of a Medium Frequency Induction Furnace?

Now, let’s talk about them one by one.

How does a medium frequency induction furnace work?

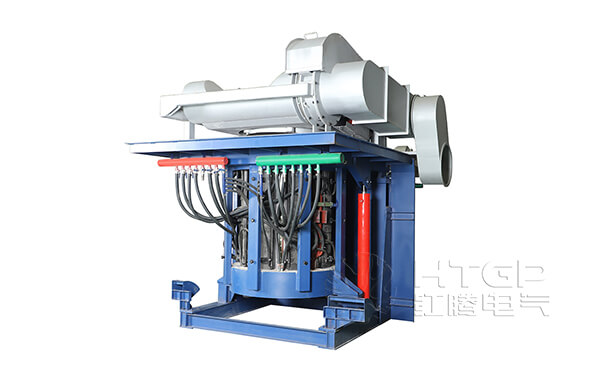

The medium frequency induction furnace is a kind of smelting equipment suitable for smelting high-quality steel and alloys. It has the advantages of fast melting speed, high productivity, strong adaptability, flexible use, good electromagnetic stirring effect, easy start-up operation, and low air pollution.

A medium frequency induction furnace operates on the principle of electromagnetic induction to generate heat. The work principle of is as follows.

Power Supply

The furnace is connected to a power supply that provides alternating current (AC) at medium frequencies, typically in the range of 1 kHz to 10 kHz.

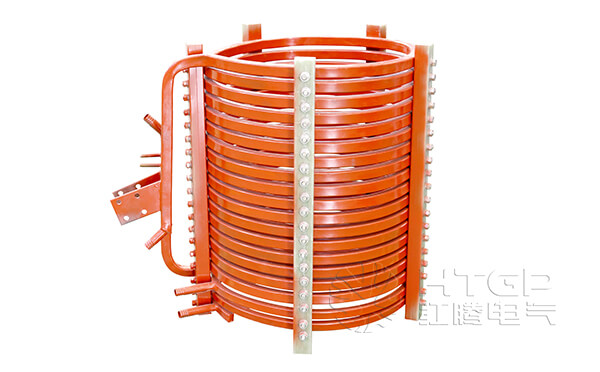

Induction Coil

The furnace contains an induction coil made of a large number of copper turns. The coil is usually wound in a helical shape and surrounds the crucible or the container in which the metal is placed.

Electromagnetic Field Generation

When the AC power supply is turned on, the alternating current flowing through the induction coil generates a rapidly changing magnetic field. This magnetic field induces eddy currents in the conductive metal placed inside the coil.

Eddy Currents

Eddy currents are circulating currents that flow within the conductive material in response to the changing magnetic field. These currents generate heat due to the electrical resistance of the material. The heat is concentrated in the metal, causing it to reach its melting point.

Melting and HeatingAs the metal is heated, it gradually melts and reaches the desired temperature. The molten metal can be used for casting, alloying, or other industrial processes. The temperature can be controlled by adjusting the power input to the furnace and the duration of heating.

What affect the melting efficiency of the Furnace?

Power of the medium frequency induction furnace

The higher the power of the furnace, the higher the melting efficiency.

Cord arrangement

The messy arrangement of the cord of the medium frequency furnace will affect the power processing capability, lead to unstable power, low power conversion rate, and affect energy consumption.

Materials to be melted

If there are 5% impurities on the surface of the material to be melted, 5% of the electrical energy will be spent to melt these impurities. This will not only reduce melting efficiency, but also affect furnace lining life.

In addition, the size of the material to be melted will also affect the melting efficiency of the medium frequency induction furnace. Generally, the size of the material to be melted is 300~500mm.

Refractory materials

The quality of refractory materials has a great impact on the loss of heat during transfer. Good quality refractory materials can effectively reduce heat loss and improve the melting efficiency of medium frequency induction furnaces.

Improper operation

The melting efficiency of the medium frequency induction furnace is the highest under rated power conditions. However, if operated improperly, the medium frequency induction furnace will not be able to reach its rated power when working, and thus it will not be able to exert its proper melting capacity.

How to improve the melting efficiency?

Increase the wall thickness of the induction coil

Thick-walled induction coils will provide more melting energy. Compared with induction coils of other cross-sections, thick-walled induction coils have a larger current-carrying cross-section, so the coil resistance is low, more energy can be used for melting, and because the wall thickness of the coil is uniform, it is stronger than a coil structure with uneven tube walls and thin side tube walls.

Reasonable design of induction coil structure

The coil is the heart of the induction furnace. The induction coil generates a strong magnetic field under the action of medium-frequency current. This magnetic field causes the metal in the furnace to generate eddy currents and generate heat. The coil is the key to converting electrical energy into heat energy, so the design of the coil is very important. Advanced coil design better focuses the magnetic field. The error between the design power of the induction coil and the actual operating power should be no more than 5%.

Use D-shaped copper tube as induction coil

The eccentric D-type copper tube produced from high-quality electrolytic copper through smelting, ingot casting, heating extrusion, rolling compression and other methods is used as the induction coil material. The purity Cu + Ag is more than 99.95%; the conductivity is more than 56MS/m (20℃).

The induction coil is wound with 99.9% eccentric D-shaped copper tube, and the melting efficiency of the medium frequency induction furnace can be increased by at least 10%.

Summary

To sum up, the intermediate frequency furnace is an efficient furnace equipment with high melting efficiency. This high efficiency mainly comes from the comprehensive effect of the working principle, performance characteristics and other related factors of the intermediate frequency furnace.