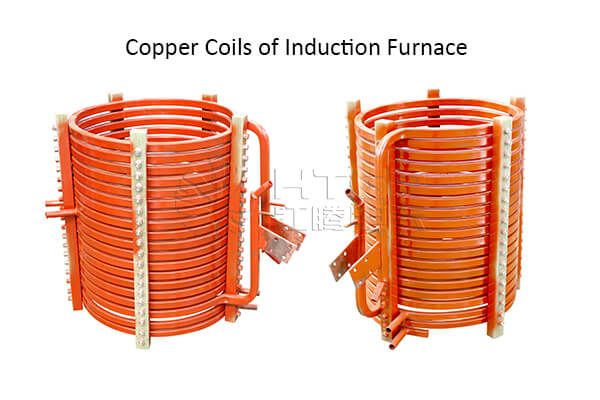

Induction furnace coils

Reactor coils

After passivation, high-quality copper tubes are wrapped with high-voltage-resistant insulation material. After forming using specialized tooling, the entire tube is wrapped with high-temperature, high-voltage insulation material. This ensures a high breakdown voltage and a long service life.

A reactor, also known as an inductor, generates a magnetic field within the space it occupies when current flows through a conductor. Therefore, all current-carrying conductors generally exhibit inductance. However, the inductance of a long, straight conductor carrying current is small, and the magnetic field generated is weak. Therefore, a typical reactor is a solenoid formed by winding wire, known as an air-core reactor. Sometimes, to increase the inductance of this solenoid, an iron core is inserted, creating an iron-core reactor. Reactance is categorized into inductive reactance and capacitive reactance. The more scientific classification is that inductive reactance (inductors) and capacitive reactance (capacitors) are collectively referred to as reactors. However, because inductors existed first and were called reactors, the term “capacitor” today refers specifically to inductors, while “reactor” refers specifically to inductors.

Product Description: Reactor coils are made from high-quality copper tubes that have undergone a passivation treatment and are then wrapped with high-voltage-resistant insulation material. After forming using specialized tooling, the entire coil is then wrapped with high-temperature, high-voltage-resistant insulation material. This ensures a high breakdown voltage and a long service life.

Intermediate frequency furnace reactor coils

Dingfeng Electric Furnace supplies reactors, medium-frequency reactors, and medium-frequency accessories. We specialize in producing reactor coils for medium-frequency, high-frequency, and industrial-frequency furnaces. The coils are wound from high-quality oxygen-free electrolytic copper tubes. Each turn undergoes a four-fold high-voltage insulation treatment with impregnation, polyimide film, mica tape, and fiberglass tape to prevent sparking or discharge. These coils are primarily used for metal smelting, heating, heat transfer, pipe bending, local and surface heat treatment, and metal corrosion protection. They offer advantages such as high frequency, compact size, light weight, easy installation, rapid start-up and shutdown, simple operation, accurate local heating, and ease of automatic control. DC smoothing reactors are critical components in medium-frequency melting equipment.

Their primary functions are: Limiting short-circuit current (the simultaneous conduction of the inverter thyristors during commutation is equivalent to a direct short-circuit of the rectifier bridge load). Without a reactor, a direct short-circuit would occur.

Suppressing the impact of medium-frequency components on the power frequency grid. Filtering (the rectified current contains an AC component), ensuring a continuous rectified output waveform and reducing current ripple. If the rectifier current is not continuous, periods of zero current will occur, causing the inverter bridge to stop operating and causing the rectifier bridge to open.

DC smoothing reactors are a crucial requirement for active inverter operation. When the inverter circuit reverses, the rectifier circuit returns the energy stored in the DC smoother to the grid through active inverter operation, protecting the inverter circuit. In practical applications, after a reactor is designed and debugged, arbitrarily adjusting its air gap and number of coil turns is prohibited. Doing so will alter the reactor’s inductance, preventing the current-limiting reactor from effectively suppressing harmonic currents and affecting the power factor. For DC smoothing reactors, this will affect the reactor’s filtering function, causing discontinuous DC current output, leading to unstable inverter bridge operation, inverter failure, and burnout of the inverter thyristors. Alternatively, in the event of a direct short circuit in the inverter bridge, the reactor’s ability to block rising current will be reduced, potentially burning out the thyristors and affecting the equipment’s starting performance.

The three types of reactors used with medium-frequency melting equipment contribute significantly to its stable and reliable operation and effectively improve the power factor. When properly combined with capacitors, the power factor can be raised to 0.95.

Our company offers reactor fabrication services for any size and specification.