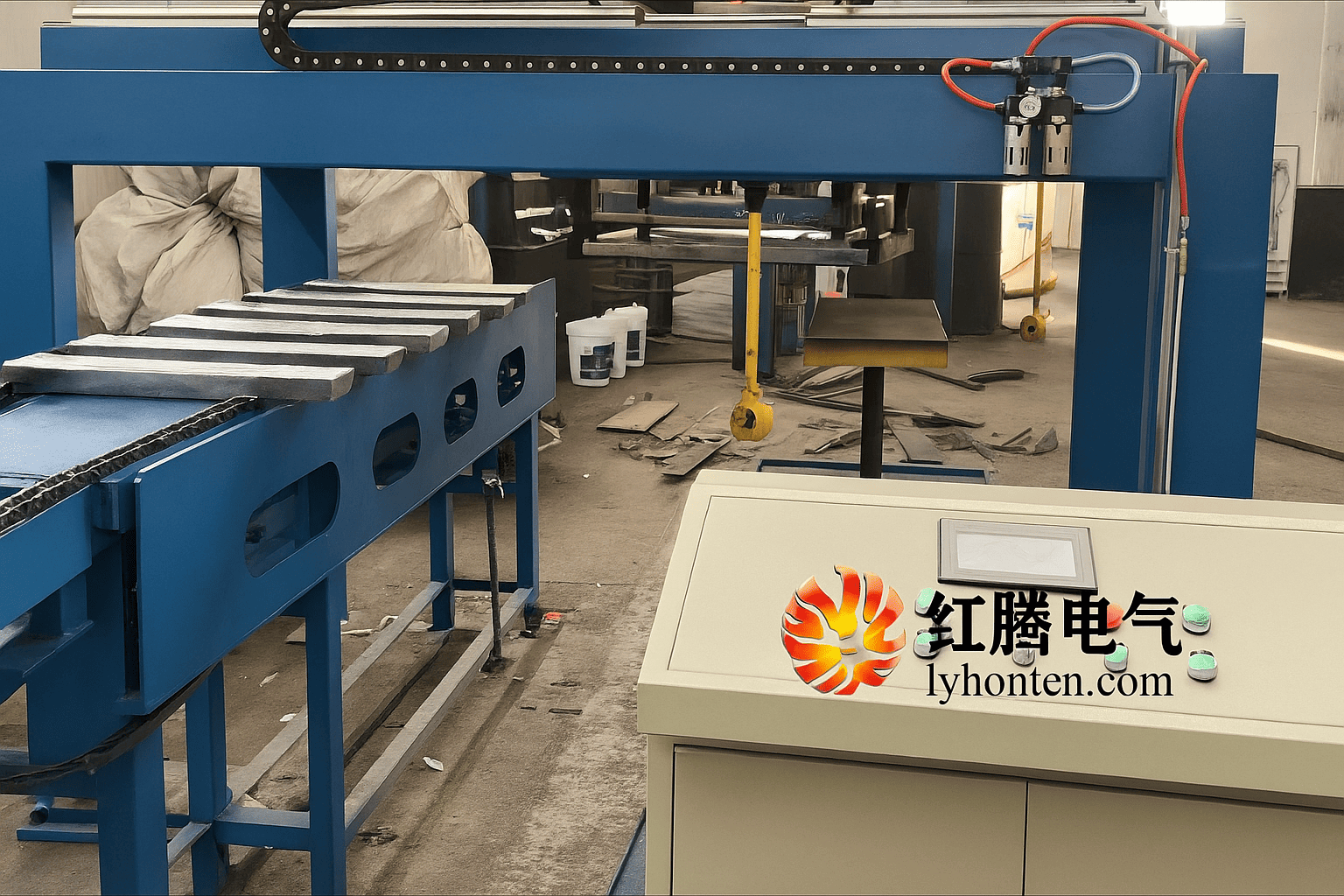

Ingot Stacker for Steel Plants

Ingot Stacker: Boosting Efficiency and Safety in Global Steel Production

In the global steel industry, efficiency, safety, and cost control are critical for maintaining a competitive edge. For international buyers seeking reliable solutions for billet and ingot handling, an Ingot Stacker is a game-changing investment. Designed for high-capacity steel plants, this equipment automates the stacking and storage of ingots, optimizing workflow from casting to rolling, while reducing labor costs and operational risks.

1. What is an Ingot Stacker?

An Ingot Stacker is a specialized piece of equipment used to lift, move, and arrange hot or cold ingots into designated storage areas or onto cooling beds. It plays a vital role in steel production lines, especially where large volumes of ingots are processed daily. By replacing manual handling with automated stacking, steel plants can achieve smoother operations and higher throughput.

2. Key Advantages for Global Buyers

For steel manufacturers in Asia, Africa, the Middle East, and South America, the Ingot Stacker offers distinct advantages that directly address the challenges of large-scale production:

-

Enhanced Safety – Minimizes human contact with high-temperature materials, reducing accident risks.

-

Operational Efficiency – Continuous automated stacking shortens cycle time between casting and rolling.

-

Labor Cost Reduction – Less manual labor needed, freeing workforce for other critical operations.

-

Precision Handling – Advanced control systems ensure uniform and stable stacking, reducing ingot damage.

-

Energy Savings – Streamlined workflow minimizes unnecessary reheating and material movement.

3. Applications in the Steel Industry

The Ingot Stacker integrates seamlessly into various stages of steel production, making it an essential part of continuous casting and rolling lines as well as standalone billet handling systems:

-

Continuous Casting Plants – Stack ingots directly after casting for controlled cooling.

-

Reheating Furnace Feed – Efficiently organize ingots for smooth feeding into rolling mills.

-

Storage Yards – Maximize yard space with precise stacking arrangements.

-

Export-Ready Bundling – Facilitate quick and organized loading for international shipping.

4. Technical Considerations When Purchasing

When sourcing an Ingot Stacker for your steel plant, international buyers should evaluate:

-

Load Capacity – Ensure compatibility with the ingot sizes and weights in your production line.

-

Automation Level – Advanced PLC-controlled systems can adapt to different stacking patterns.

-

Material Compatibility – Verify suitability for hot and cold ingots.

-

Maintenance Requirements – Choose designs with easy-access components for reduced downtime.

-

Supplier Support – Confirm availability of spare parts, training, and after-sales service.

5. Strategic Benefits for B2B Buyers

In international trade, an investment in an Ingot Stacker is not just a purchase—it’s a long-term efficiency strategy. By integrating automated stacking into your steel production process, you can:

-

Increase daily output capacity without expanding your workforce.

-

Improve delivery times, strengthening your reputation with overseas buyers.

-

Reduce operational hazards, aligning with global safety standards.

-

Optimize space usage, lowering facility expansion costs.

6. Conclusion

The Ingot Stacker is more than just a handling machine—it is a productivity booster, safety enhancer, and profit driver. For B2B buyers engaged in cross-border steel equipment procurement, choosing a high-quality Ingot Stacker from a trusted manufacturer ensures sustainable growth, operational stability, and a competitive advantage in the global market.