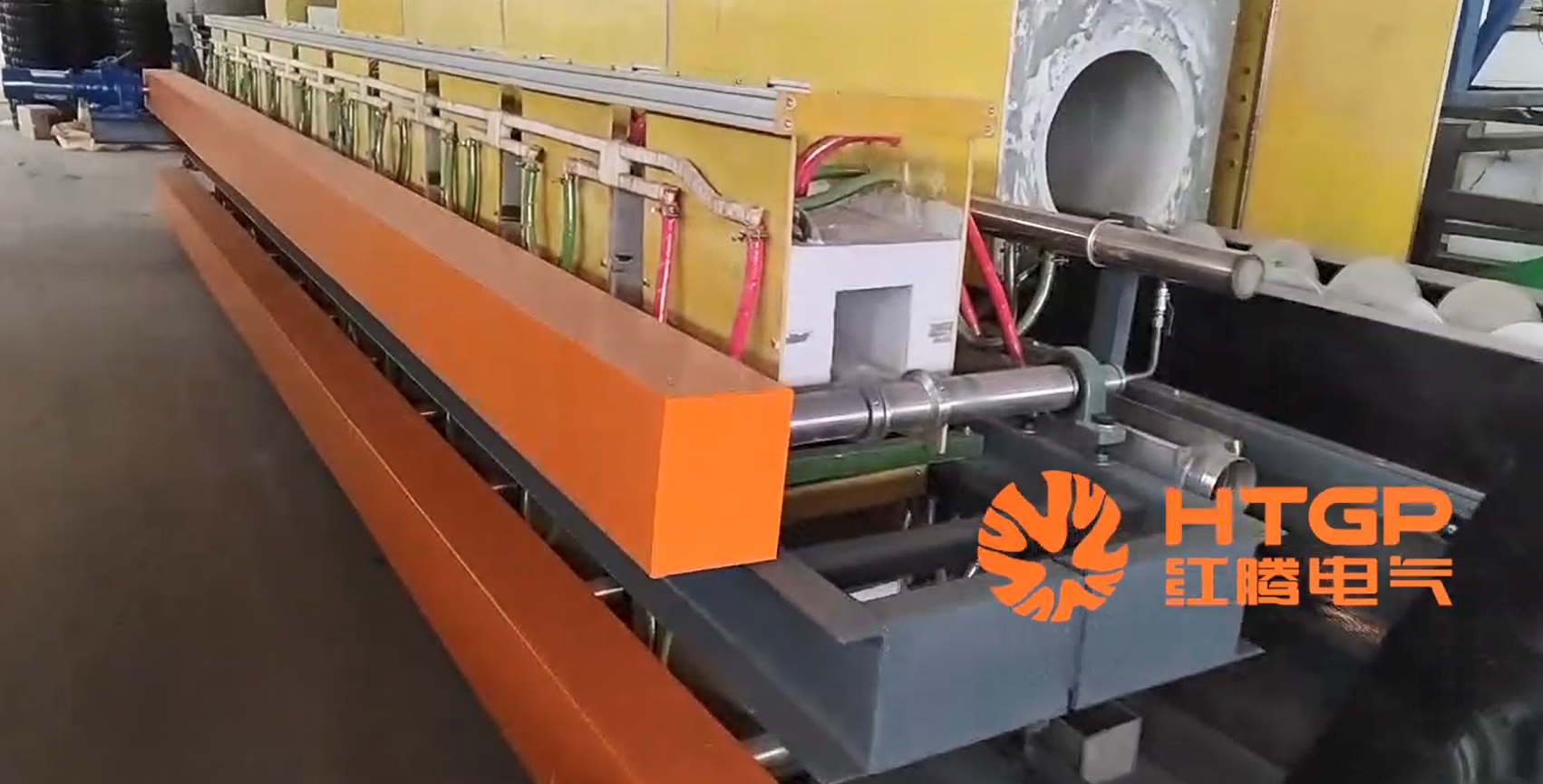

Steel billet all-in-continuous casting machine

Steel Billet All-in-Continuous Casting Machine: Advanced Solution for Modern Steelmaking

In the evolving world of steel manufacturing, efficiency, quality, and automation are key drivers of competitiveness. One of the most revolutionary advancements in modern steel plants is the Steel Billet All-in-Continuous Casting Machine — an integrated, automated solution designed to transform molten steel into high-quality billets in a continuous, streamlined process. This article presents a strategic product plan for marketing this technology to international buyers and industrial users.

What is a Steel Billet All-in-Continuous Casting Machine?

A Steel Billet All-in-Continuous Casting Machine is a complete system that casts molten steel directly into billets of specific sizes and shapes without intermediate handling. Unlike traditional batch casting methods, this continuous casting machine integrates all necessary processes into a single, uninterrupted operation.

It is called “All-in” because it typically combines:

-

Ladle turret & tundish

-

Mold oscillation system

-

Secondary cooling zone

-

Withdrawal and straightening system

-

Cutting and billet discharge equipment

This integration reduces human intervention, shortens production time, and guarantees better metallurgical consistency.

Key Features and Components

Our advanced steel billet continuous caster is designed for small to medium steel mills seeking flexibility, automation, and high output with minimal waste.

1. Ladle Turret and Tundish System

-

Supports multiple ladles for seamless steel flow

-

Equipped with slide gate systems for flow control

-

Tundish preheating system to maintain temperature

2. Mold Section

-

High-performance copper molds with water-cooled jackets

-

Hydraulic oscillation with programmable stroke and frequency

-

Mold level control (MLC) system to stabilize casting process

3. Secondary Cooling Zone

-

Water spray and mist cooling system

-

Thermocouple monitoring for billet surface temperature

-

Adjustable spray patterns for different steel grades

4. Withdrawal and Straightening Unit

-

Servo-controlled rollers for synchronized billet extraction

-

Curved and straight mold options based on layout

-

Heavy-duty gearboxes and drives

5. Cutting and Discharge Section

-

Torch or hydraulic shear cutting system

-

Automatic billet length adjustment

-

Hot billet discharge rollers to cooling bed or stacking

Technical Specifications (Typical)

-

Casting speed: 1.5 – 3.5 m/min

-

Billet size: 100×100 mm to 200×200 mm

-

Number of strands: 1 to 8 strands (customized)

-

Steel grades: Carbon steel, alloy steel, stainless steel

-

Production capacity: 10,000 – 500,000 tons/year

Product Advantages

High Efficiency and Automation

Fully automatic systems reduce manpower needs and enable 24/7 continuous operation. Remote monitoring and PLC/SCADA control ensure real-time diagnostics and optimization.

Improved Billet Quality

Accurate temperature control, optimized cooling, and mold oscillation minimize internal cracks, segregation, and surface defects. The result is metallurgically sound billets suitable for forging, rolling, or machining.

Flexible Configuration

Available in single or multi-strand versions, curved or straight designs, and different billet dimensions depending on client production needs and layout.

Compact Layout

The all-in-one design requires less footprint and infrastructure investment compared to traditional setups, making it ideal for space-limited steel plants.

Target Customers and Applications

This product is tailored for:

-

Steel mills expanding their billet production lines

-

Mini-mills processing scrap and DRI (direct-reduced iron)

-

Re-rolling mills needing in-house billet casting

-

Engineering contractors supplying turnkey steel plants

Main application sectors include:

-

Long steel product manufacturing (rebar, wire rod, angles)

-

Automotive and structural steel production

-

Export-grade billet trading

Global Market Focus

Target export regions include:

-

South Asia: India, Pakistan, Bangladesh

-

Middle East: Saudi Arabia, UAE, Iran

-

Africa: Egypt, Nigeria, South Africa

-

Eastern Europe: Ukraine, Serbia, Turkey

-

South America: Brazil, Chile, Peru

These regions show high demand for local billet manufacturing to reduce import dependence and boost domestic steel value chains.