What Is an Induction Billet Heater?

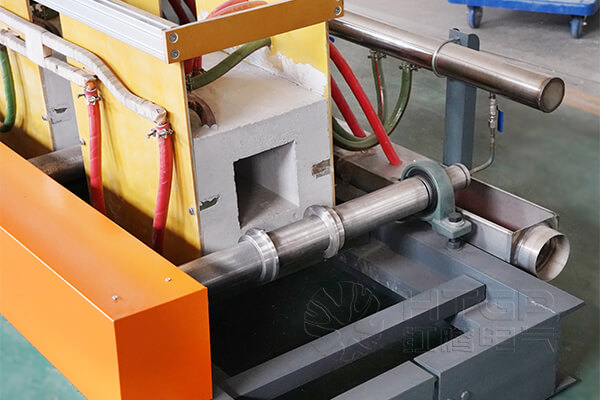

An induction billet heater is a device used to heat billets, which mainly consists of induction coils, power supply, and control parts. It uses electromagnetic induction heating technology. When the induction coil is supplied with alternating current, an alternating magnetic field will be generated, causing eddy currents to be generated inside the billet, thereby heating the billet.

An induction billet heater has the advantages of fast heating speed, high efficiency, energy saving, and environmental protection. It can heat the steel billet to the required temperature quickly, improving production efficiency. At the same time, due to the use of electromagnetic induction principles, the induction billet heater does not need to be in direct contact with the billet, reducing heat loss and oxidation.

Characteristics of Induction Billet Heater

Fast heating speed: Using electromagnetic induction heating technology, the heating speed is several times faster than traditional heating methods.

Energy saving and environmental protection: Due to the use of electromagnetic induction heating technology, there is no need for direct contact with the steel billet, which reduces heat loss and oxidation, while also reducing energy consumption and environmental pollution.

High-temperature control accuracy: Using an advanced temperature control system, precise temperature control can be achieved to ensure product quality.

Easy to operate: Using an automated control system, remote monitoring and operation can be achieved, which is convenient and fast.

Easy maintenance: The equipment has a simple structure and is easy to maintain, reducing maintenance costs.

How to Choose an Induction Billet Heater?

There are several factors to consider when choosing an induction billet heater.

Heating requirements: First of all, it is necessary to determine the type, size, and quality requirements of the steel billet that needs to be heated. Different billet heating furnaces have different application ranges and power output capabilities. Make sure the furnace you choose can meet your heating needs.

Power and frequency: Select the appropriate power and frequency based on specific application needs. Generally speaking, the greater the power, the faster the heating speed, but it will also increase energy consumption and equipment costs.

Heating efficiency: Consider the heating efficiency of the equipment to ensure that production requirements can be met and energy consumption reduced.

Control system: Choosing equipment with high-precision temperature control systems and automation functions can improve production efficiency and product quality.

Manufacturer and after-sales service: Choosing a manufacturer with a good reputation and after-sales service can ensure the quality of the equipment and after-sales service.

When selecting an induction billet heater, factors such as the reliability, stability, and safety of the equipment also need to be considered. It is recommended to learn more about the relevant technical specifications and the operating manual provided by the manufacturer before purchasing so that you can select and use the equipment correctly.

Common Applications of Induction Billet Heater

Induction billet heaters are widely used in industrial fields such as billet preheating, heat treatment, forging, and hot forming.

Preheating of steel billet: Before rolling, preheating the steel billet through an induction heating furnace can improve rolling efficiency and product quality.

Heat treatment of steel billet: Heating the steel billet through an induction heating furnace can realize quenching, tempering, and other heat treatment processes of the steel billet to improve the hardness and toughness of the steel billet.

Forging and hot forming of steel billets: During the forging and hot forming process, the steel billet is heated through an induction heating furnace, which can improve the process ability and forming quality of the material.

Service Life of Induction Billet Heater

The service life of an induction billet heater is usually more than 5 years, and it will be longer if it is well maintained. The specific service life will be affected by many factors, such as equipment quality, usage environment, maintenance, etc. Therefore, to extend the service life of the induction billet heater, regular maintenance is required to ensure that the equipment is in good working condition.

Induction Billet Heater Maintenance

To extend the service life of the induction billet heating furnace, regular maintenance work is essential.

Regularly check the working status of each component of the equipment, including electric heating coils, capacitors, sensors, etc., to ensure their normal operation.

Regularly clean the dust and debris inside the equipment to keep it clean.

Regularly check the electrical connections and insulation of the equipment to ensure safe operation.

Regularly check the equipment’s cooling system to ensure a smooth flow of cooling water and prevent the equipment from overheating.

Perform regular maintenance on the equipment, including replacing worn parts, cleaning the inside of the equipment, etc.

At Last

An induction billet heater is an efficient, energy-saving, and environmentally friendly heating equipment, suitable for heating billets of various specifications and materials. When using induction billet heating furnaces, you need to pay attention to safety issues and perform regular maintenance.