How to Determine the Desired Capacity of the Rebar Rolling Machine?

Rebar (short for reinforcing bar) is a critical component used in reinforced concrete structures to provide strength and durability. When building bridges, highways, infrastructure projects, and other constructions, we always need rebar.

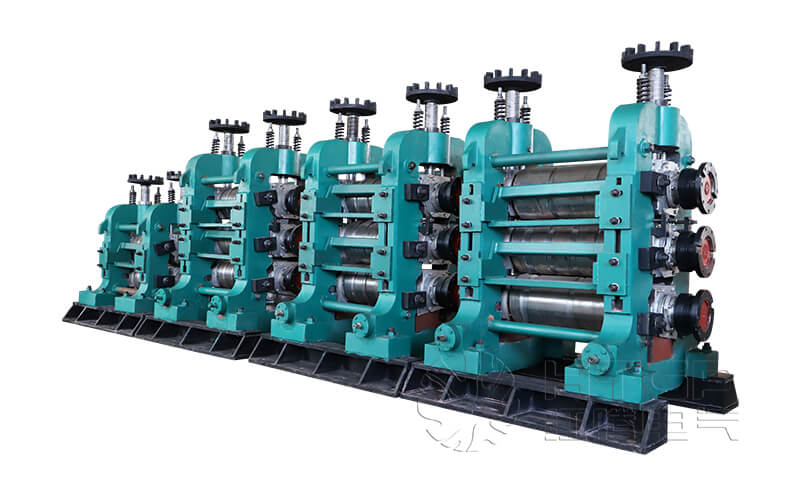

Therefore, the rebar rolling machine, producing rebar, is widely wanted all over the world. Then, do you know how to determine the desired capacity of the rebar rolling production line?

In this article, we will introduce to you several specific factors that you should consider when determining the desired capacity.

Production VolumeAssess your production requirements, including the volume of rebar you need to produce within a given time frame. The machine’s capacity should align with your production goals to ensure efficient and timely output.

Bar Size and WeightConsider the range of rebar sizes and weights you intend to produce. Different machines have different capabilities when it comes to handling various bar sizes and weights. Ensure that the machine you choose can accommodate your specific requirements.

Equipment CapabilitiesConsider parameters such as the maximum tonnage of the steel bar rolling mill, rolling speed range, main motor power, etc. These parameters determine the upper limit of the rolling mill’s production capacity. Based on your production needs, make sure the rolling mill you choose has the capabilities to meet your needs.

Material StrengthEvaluate the strength and hardness of the materials you plan to roll. Some rebar rolling machines are designed for specific material types or have limitations based on the strength of the steel. Ensure that the machine you select can handle the material strength you’ll be working with.

Automation and EfficiencyDetermine the level of automation and efficiency needed for your operations. Advanced machines often come with features such as automated feeding, cutting, and stacking, which can improve productivity and reduce labor costs. Consider whether these features are important to your operations and factor them into your capacity requirements.

Energy SupplyConsider the supply stability of electricity, water, gas, and other energy sources. These energy sources are essential in the steel rolling process. Ensure a stable energy supply to avoid disruptions to production capacity due to energy outages.

Available SpaceAssess the space available in your facility for the machine installation. Larger-capacity machines may require more space for operation, maintenance, and safety considerations. Ensure that your facility can accommodate the size and layout requirements of the machine you choose.

BudgetYour budget will also play a significant role in determining the desired capacity of a rebar rolling machine. Higher-capacity machines with advanced features typically come at a higher cost. Balance your production requirements with your budget constraints to find the most suitable capacity for your needs.

By considering these factors, you can determine the desired capacity of a rebar rolling machine that aligns with your production goals, material requirements, available space, and budget.