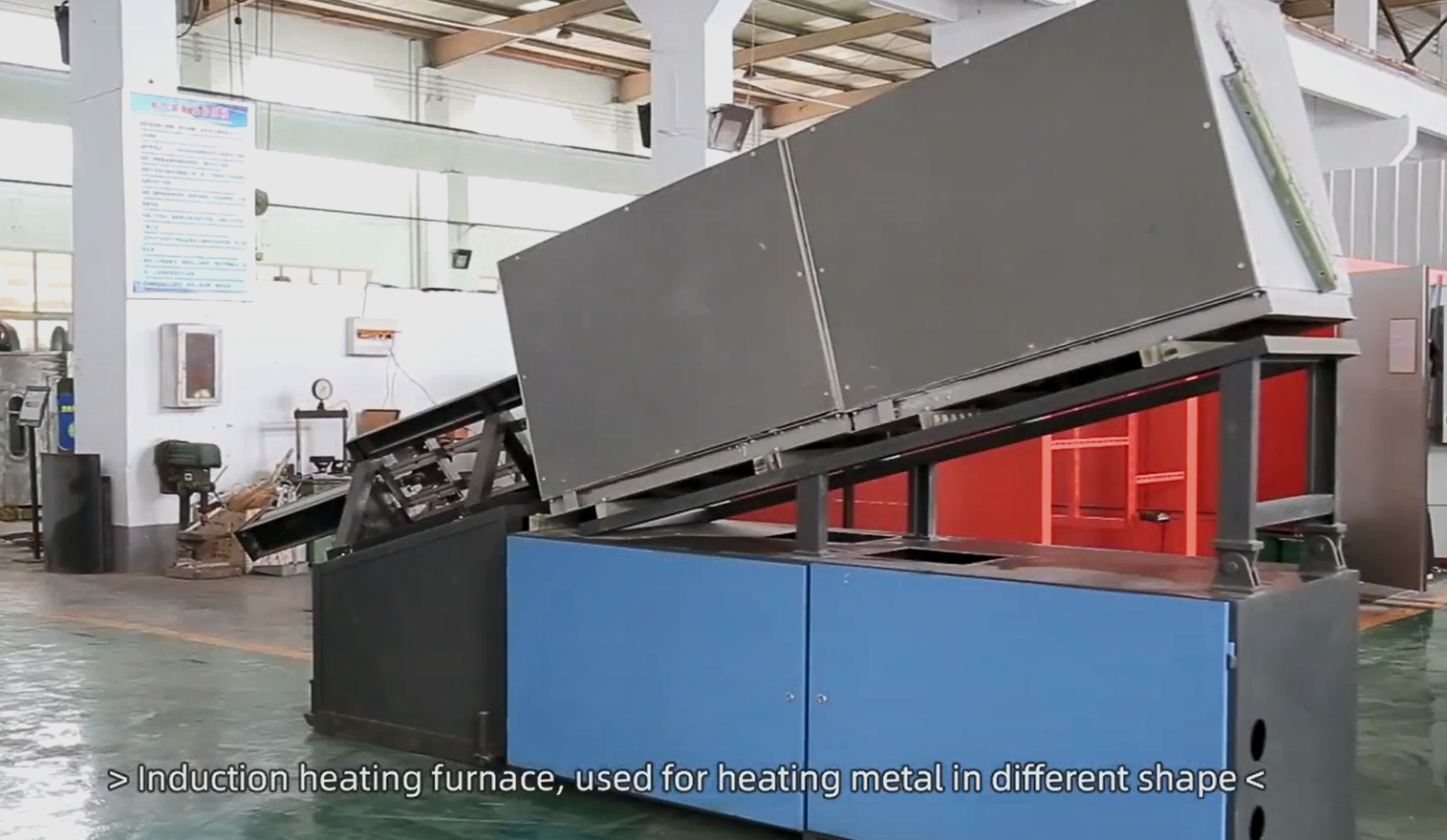

Induction smelting equipment

I recall my early days in the foundry industry, standing near the intense, almost primal heat of a traditional cupola furnace. The process was an art form learned over generations, but it was also loud, imprecise, and at the mercy of many variables. The transition I have witnessed since then, driven by advancements in electrical and electronic engineering, has been nothing short of transformative. The central figure in this revolution is the induction furnace, a technology that has progressively brought a level of precision, efficiency, and control to metal smelting that was once unimaginable.

This journey from raw power to refined control is a story of technological evolution. If you are considering an investment in induction smelting, you are likely navigating a landscape of varied and complex options. This guide is the distillation of my experience, designed to walk you through the practical realities of this equipment, moving beyond technical specifications to help you understand which solution truly fits your operational needs. It is the conversation I wish I could have had when I was first tasked with modernizing a melt shop.

The Core Technology: An Overview of Induction Smelting Equipment

At its heart, induction smelting is a remarkably clean and contained process. It relies on the principles of electromagnetic induction to generate intense heat directly within the metal itself, without direct contact with a heating element. This fundamental principle has given rise to a diverse family of furnaces, each optimized for different scales and materials.

The progress has been relentless. Where we once only had small, specialized units, the industry now boasts massive power-frequency furnaces for large-scale iron casting and highly sophisticated vacuum induction furnaces for producing aerospace-grade superalloys. We must acknowledge, however, that this is not a one-size-fits-all technology. The capital investment can be significant, and the choice of frequency and furnace type has profound implications for your energy costs, material compatibility, and operational flexibility.

An Operational Perspective: What the Datasheets Do Not Tell You

To truly understand these machines, one must consider the daily rhythm of operating them.

A low-frequency (power frequency) furnace, for instance, feels like a battleship. It requires a continuous “heel” of molten metal to operate efficiently, making it ideal for continuous, single-product campaigns. In contrast, a modern medium-frequency furnace feels like a nimble sports car. It can be started from cold, melted down completely, and be ready for a different alloy in the next heat. The level of control is palpable; an experienced operator can precisely manage temperature and chemistry, which is a world away from the more reactive methods of the past.

My experience with vacuum induction melting (VIM) was another leap entirely. The process is quieter, almost clinical. The entire operation takes place within a sealed chamber, removing the atmospheric gases that are the enemy of reactive metals and superalloys. The result is a level of purity and metallurgical integrity that is simply unattainable in an open-air furnace. This, however, comes at the cost of complexity and a significantly longer cycle time.

Key Advantages of Modern Induction Smelting

- Superior Metallurgical Quality: Precise temperature control and electromagnetic stirring action produce a highly homogeneous and clean molten metal bath.

- High Energy Efficiency: Heat is generated directly within the charge material, minimizing thermal loss.

- Operational Flexibility: Medium-frequency furnaces in particular allow for quick startups and alloy changes.

- Enhanced Environmental and Safety Profile: The process is clean, quiet, and produces far fewer emissions compared to fossil fuel-fired furnaces.

How to Select the Right Induction Smelting Equipment

Choosing a furnace is a long-term strategic decision. Base your choice on a rigorous analysis of these key factors.

- Your Primary Alloy and Product: The type of metal you melt is the single most important factor. Cast iron has different requirements than a nickel-based superalloy.

- Required Capacity and Throughput: Be realistic about your daily or weekly production targets. This will determine the necessary furnace size (e.g., 3-ton, 5-ton) and power rating.

- Operational Flexibility Needs: Do you produce a single alloy continuously, or do you need to switch between different materials frequently? This is the key deciding factor between a power-frequency and a medium-frequency system.

- Purity and Quality Requirements: For standard castings, an open-air furnace is sufficient. For aerospace, medical, or electronic applications, a vacuum furnace is non-negotiable.

- Power Infrastructure and Cost: A large induction furnace is a significant electrical load. Your facility must have the available power capacity. The choice of technology will also directly impact your ongoing energy consumption.

A Recommended Path for Furnace Selection

Based on my experience guiding foundries through this process, I suggest evaluating the options in the following order of priority.

1. The Medium-Frequency Induction Furnace

For the vast majority of modern foundries and specialty melt shops, this is the superior and most versatile choice. Its ability to start from a cold charge provides unmatched flexibility, making it perfect for businesses that need to adapt to changing customer orders. The energy efficiency is excellent, and the rapid melting cycles maximize productivity. It represents the optimal balance of flexibility, control, and cost for producing high-quality cast iron, steel, and most non-ferrous alloys.

2. The Power-Frequency Induction Furnace

This is the established workhorse for large-scale, continuous production of a single material, most commonly cast iron. If your business model is based on high-volume, low-variety output, the operational simplicity and sheer capacity of a power-frequency unit are compelling. Its lower capital cost per ton can be attractive, but this is offset by its lack of operational flexibility.

3. The Vacuum Induction Furnace (VIM)

This is a specialized instrument for the high-end of the market. The decision to invest in a VIM is driven entirely by the need for absolute material purity. If you are in the business of producing superalloys, medical-grade implants, or materials for the electronics industry, a VIM is not just an option; it is a necessity. The complexity and cost are significant, but it unlocks a market segment inaccessible with other technologies.

4. The Plasma Induction Furnace

This represents the frontier of induction technology. It is a niche, highly specialized tool used primarily for research and the production of small batches of extremely high-purity metals. For most commercial operations, it is not a practical consideration, but it is important to be aware of its capabilities as a refining tool.

The journey of induction smelting technology reflects the broader evolution of manufacturing, from brute force to intelligent precision. The growth of global manufacturing hubs, including the established electric furnace industry in China with centers in LuoYang, Xiangtan, and Shanghai, continues to drive innovation and accessibility. Choosing the right furnace is a defining decision for your operation, one that will shape your capabilities, efficiency, and market position for years to come.