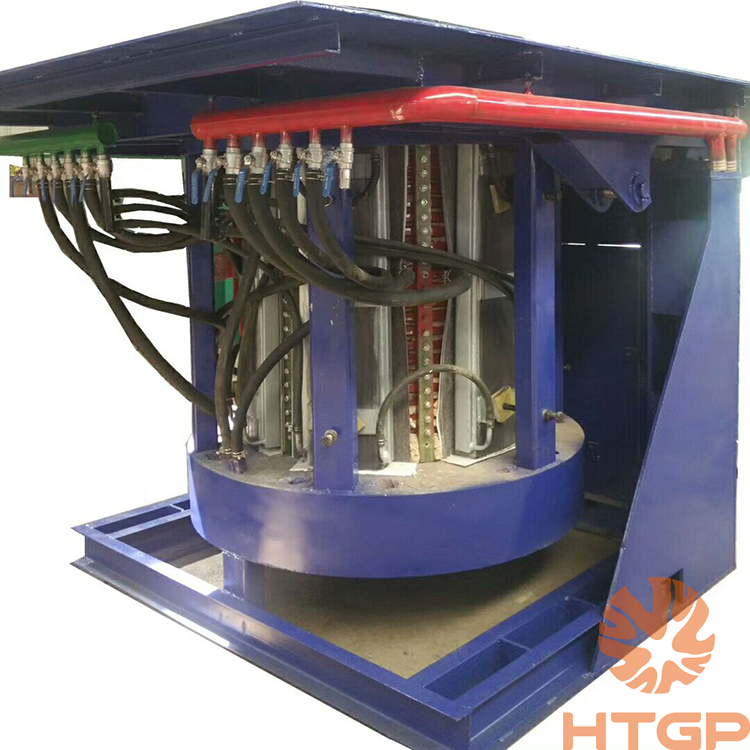

Steel shell intermediate frequency furnace

Steel shell induction intermediate frequency furnace is one of our main heating equipment.

As an industrial furnace for heating metal, the overall stability of the steel shell furnace is good, firm and not easy to damage, and strong in safety.

Our electric furnace generally adopts the principle of electromagnetic induction, so when working, the noise of the furnace body is very low and the working environment is good.

The design of the furnace table above the horizontal height makes the charging more efficient.

The intermediate frequency electric furnace is carefully designed according to the different requirements of various metal smelting. Users can choose various specifications of induction coils for intermediate frequency electric furnaces, and rationally choose the wall thickness and specifications of copper pipes, so as to improve the utilization rate of electric energy.

The exquisite coil design makes the power conversion efficiency, selects the correct cross-sectional shape of the coil for different applications, and also provides more melting energy for thick-walled induction coils.

The coil of the intermediate frequency electric furnace is lengthened, which can cover more than 60% of the magnetic field around it, reducing heat loss. The solid coil support design eliminates the possibility of inter-turn short circuits, greatly extending the life of the furnace lining.

You can choose to use a stove cover to minimise heat loss.

In terms of electrical cabinets, this steel shell furnace adopts variable frequency power supply. The control system adopts high-performance, high-density, large-scale special-purpose integrated modules. The stability of the circuit is good, the anti-interference ability is strong, and the response speed is fast.

The steel shell intermediate frequency electric furnace adopts the protection function of the steel shell to provide high safety, and the unique design of the water-cooled cable end of the intermediate frequency electric furnace improves the safety and service life of the system.

The electric furnace is connected with a water-cooled cable of suitable size, so that the displacement of the water-cooled cable is minimized when the furnace is tilted, and the service life is improved. The economic benefits of users can be maximized.

Hongteng is a manufacturer specializing in the production of intermediate frequency furnaces. If you are interested in us, you can choose to pay attention to us for a long time, and we will provide you with good services.

Video of the use process of the furnace