What Is an Induction Billet Heating Furnace?

The induction billet heating furnace is a non-standard heating equipment that uses the principle of electromagnetic induction to heat the billet and then roll it. It is generally used in conjunction with the billet rolling equipment to form a billet heating and rolling production line. The induction billet heating furnace has mature induction heating technology, high-quality raw materials, and a closed-loop temperature control system. Next, Luoyang Hongteng will introduce to you in detail what is an induction billet heating furnace.

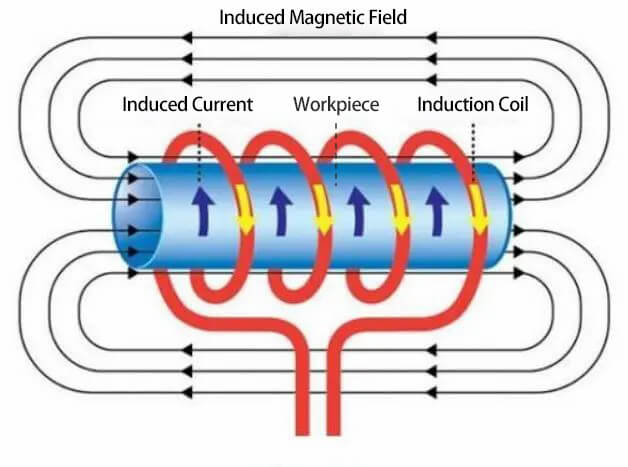

Principle of Induction Billet Heating Furnace

The induction billet heating furnace adopts the organic combination of thyristor frequency conversion device and induction heating coil and generates frequency conversion current through the frequency conversion device. This frequency conversion current will generate a magnetic field through the spiral induction coil, thereby forming an eddy current inside the billet, and the current flows in the billet so that the self-heating of the billet achieves the purpose of billet heating.

Application of Induction Billet Heating Furnace

1. The material of the billet heated by the induction billet heating furnace is cast steel, cast iron, alloy aluminum, stainless steel, and alloy copper. It is suitable for heating various billets before rolling, such as online replenishment heating of continuous casting billets and heating of steel billets.

2. The shape of the billet heated by the induction billet heating furnace is mainly round billet, square billet, steel billet, and steel billet.

Composition of Induction Billet Heating Furnace

The induction billet heating furnace is composed of a thyristor variable frequency power supply, billet heating coil, billet conveying machinery, Siemens PLC control system, infrared temperature measurement system, cooling circulation system, and so on.

Heating Temperature of Induction Billet Heating Furnace

According to different applications, the billet heating temperature range is different.

Cold Billet HeatingThe induction billet heating furnace needs to heat the billet from room temperature to 1200°C for rolling.

On-line Billet HeatingAfter the billet is discharged from the continuous casting machine, it needs to be reheated before charging and rolling. Therefore, the induction billet heating furnace plays an important role in heating the billet to the rolling temperature, which is what we often call billet heating. The heating temperature is generally heated from 800°C to 1200°C, which means that the billet temperature rises only 400°C.

Heating Power of Induction Billet Heating Furnace

The induction billet heating furnace is a non-standard heating equipment, and the heating power varies according to the billet heating temperature, heating time, and heating efficiency. Therefore, the power configuration of the induction billet heating furnace must be designed and calculated according to the actual needs of users. Generally speaking, the billet is heated at room temperature.

Advantages of Induction Billet Heating Furnace

Induction billet heating furnace has the characteristics of fast heating, accurate heating temperature, low carbon environmental protection, high efficiency and energy saving, temperature controllable, repeatable operation, high degree of automation, high billet utilization rate, simple and convenient operation, etc.

Energy Efficiency

Induction heating is highly efficient compared to other heating methods. It uses electromagnetic fields to directly heat the billet, minimizing heat loss and reducing energy consumption. This efficiency can result in significant cost savings in terms of energy bills.

Rapid Heating

Induction heating provides rapid and precise heating of billets. The heating process is typically faster compared to traditional methods such as gas or electric furnaces. It allows for quick heat-up times and improved production rates, leading to higher productivity.

Consistent Heating

Induction heating provides uniform and consistent heating throughout the billet. The electromagnetic field evenly distributes heat, eliminating hot spots and ensuring consistent metallurgical properties across the billet. This is particularly important for applications where temperature control is critical.

Controllable Heating Parameters

Induction heating furnaces offer precise control over heating parameters such as temperature, heating time, and heating patterns. This level of control allows for customization and optimization of the heating process to meet specific requirements of different billet materials and applications.

Compact and Space-Saving Design

Induction heating systems are compact and require relatively less floor space compared to other types of furnaces. This is particularly advantageous in facilities with limited space.

Clean and Environmentally Friendly

Induction heating is a clean and environmentally friendly heating method. It does not involve the combustion of fossil fuels or the production of harmful emissions, making it a greener option compared to fuel-fired furnaces.

Reduced Maintenance

Induction heating systems have fewer moving parts compared to other heating systems, resulting in lower maintenance requirements. This can lead to reduced downtime and increased operational efficiency.

Safe Operation

Induction heating eliminates the need for open flames or heating elements, reducing the risk of accidents and improving workplace safety. The absence of open flames also reduces the risk of material contamination.

It should be noted that as a kind of electrical equipment, an induction billet heating furnace needs to pay attention to safety and hygiene issues when using it and avoid dangers such as burns and electric shocks. At the same time, it should be installed and used according to the requirements of the manual to avoid damage to the equipment and affect the service life. If there is a failure or problem, it should be stopped in time for inspection and seek help and guidance from professionals.