What Should I Do if the Copper Induction Coil Leaks of Melting Furnace?

The Medium frequency melting furnace will inevitably encounter such and other problems during use of the Medium frequency melting furnace. Common accidents include furnace leakage and furnace wear. How should the copper induction coil leakage repair be carried out? The following editor will introduce to you the repair method of Medium frequency melting furnace copper induction coil leakage.

Causes of Water Leakage in Copper Induction Coil

-

The coil structure causes

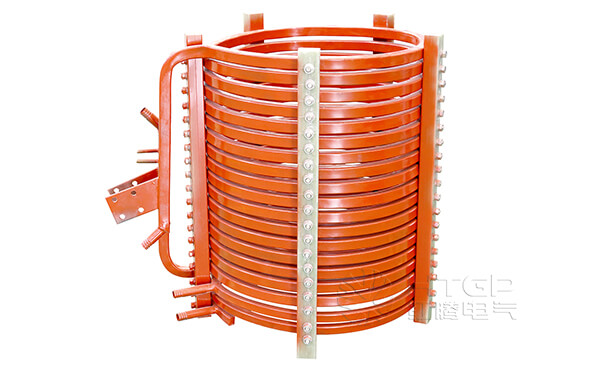

The induction coil of the Medium frequency melting furnace is made of a copper tube wound into multiple circles, with 5-8 copper screws on each circle, and insulating Bakelite connections in the middle. If there is a shortage of screws on the induction coil during use, it may cause electromagnetic vibration of the induction coil, which will continuously hit the furnace lining, resulting in loosening and cracking of the furnace lining material, water seepage, and furnace penetration.

-

Furnace charging problem

The interior of the medium-frequency melting furnace is composed of a furnace charge and an induction coil. The furnace shell is divided into two pieces, left and right, with eight stainless steel screws and some asbestos pads connected between them. When the eight screws or asbestos pads are loose, the furnace shell will be distorted. As a result, the coil leaks or even the phenomenon of molten iron passing through the furnace occurs.

-

The quality of insulating Bakelite is not good enough

The insulating bakelite is located at the connection between the coils of the induction coil and plays a role in supporting the weight of the entire induction coil, lining material, and molten iron. Once the weight to be borne cannot be supported, the bending of the insulating wood will affect the stability of the induction coil. The furnace lining is loose and cracks appear, resulting in the leakage of molten iron and water leakage from the induction coil.

The Solution to the Leakage of the Copper Induction Coil

-

Cooling: First determine the location of the specific water leakage, transfer the molten iron being smelted in the furnace, and cool the furnace body.

-

Leakage repair: judge the damaged area of the coil induction coil. If it is small, you can choose the way of welding to repair the leak. If the damaged area is large, you need to replace the induction coil.

-

Cleaning: The working environment of the induction coil is relatively harsh, especially at the casting site. It is inevitable that there will be dust and iron filings falling on the coil of the Medium frequency melting furnace, causing short circuits between turns or carbonization of the surface of insulating bakelite, causing ignition between turns, so it is necessary to Do a good job of cleaning to prevent iron filings or iron slag from falling on the Medium frequency melting furnace coil.

-

Replacement: For induction coils that cannot be repaired, they should be replaced in time to avoid dangerous situations such as serious water leakage and furnace wear.

Precautions for Maintenance of Copper Induction Coil

-

Pay attention to the replacement environment. During the replacement process, attention should be paid to the cleaning of dust and iron filings. The focus is on the coil to prevent iron filings or iron dross from falling on the Medium frequency melting furnace coil.

-

Pay attention to the direction of the coil cooling water inlet, bottom in and top out, and avoid waterway topping, to ensure that there is a certain pressure of cooling water in the coil.

-

Pay attention to the condition of the furnace lining. After the furnace lining is broken, the metal oxide skin falling on the coil will also cause inter-turn short circuits or even furnace wear-through. Therefore, other components should also be repaired during the maintenance process to avoid other failures.

The above is the editor’s analysis of the maintenance method of the induction coil leakage of the Medium frequency melting furnace and the cause of the failure. The leakage of the induction coil is also very dangerous to the production of the Medium frequency melting furnace. During our daily use, we should perform regular maintenance and planned overhauls to ensure production safety.