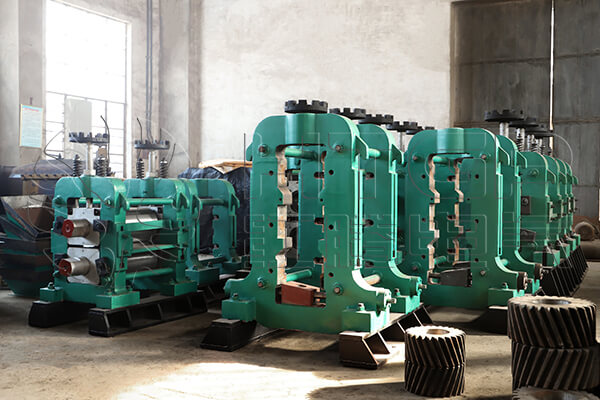

What Products Can the Hot Rolling Mill Machine Roll?

With the development of the steel rolling industry, the hot rolling mill machine is widely used in the continuous casting and rolling production line. Due to the excellent properties of high strength, good toughness, easy processing, and good weldability, hot-rolled steel products are widely used in manufacturing industries such as ships, automobiles, bridges, constructions, machinery, and pressure vessels.

Hot rolling is to use slabs (mainly continuous casting slabs) as raw materials, and after heating, the rough rolling unit and the finishing rolling unit are used to make strip steel or steel bars. With the increasing maturity of new control technologies such as hot-rolled dimensional accuracy, plate shape, and surface quality, and the continuous emergence of new products, hot-rolled steel sheets and strip products have been more and more widely used and have become more and more competitively in the market. So, what products can the hot rolling mill machine roll?

Hot Rolling Mill Machine Final Products

There are many products that can be rolled by hot-rolled steel machines. According to the material and performance of rolled products, they can be divided into the following categories.

a) Ordinary carbon structural steel

b) low alloy steel

c) alloy steel

According to the use of rolled products, the final products can be divided into the following categories.

a) Steel for cold forming

b) Structural steel

c) Automotive structural steel

d) Corrosion-resistant structural steel

e) Steel for mechanical structures

f) Steel for welding gas cylinders and pressure vessels

g) Pipeline steel

Advantages and disadvantages of hot rolling

Advantages

1. Low energy consumption, good plastic processing, low deformation resistance, no obvious work hardening, easy rolling, and reduced energy consumption required for metal deformation.

2. Hot rolling usually uses large ingots and large reductions for rolling. The production rhythm is fast and the output is large, which creates conditions for large-scale production.

3. The as-cast structure is transformed into a processed structure through hot rolling, and the plasticity of the material is greatly improved through the transformation of the structure.

4. The characteristics of the rolling method determine that there is anisotropy in the properties of the rolled sheet. First, there are obvious performance differences in the longitudinal, transverse, and high directions of the material. Second, there are deformation textures and recrystallization textures. There is an obvious directionality in control performance.

Shortcomings

High-temperature rolling produces an iron oxide scale, which makes the metal surface quality not smooth enough; the size of the product is not accurate enough, and the mechanical properties are not as good as cold processing.

Hot rolling mill Machine Operating Efficiency

In the operation of the rolling mill, in order to improve the operating efficiency of the high-speed rolling mill, it is necessary to carry out corresponding improvement measures. The operating efficiency of rolling mills is mostly affected by unplanned shutdowns, other equipment delays, roll and bearing replacement, and other process maintenance. Therefore, we have the following suggestions for improving the operating rate of high-speed rolling mills.

1. The material of the roll should be screened according to the requirements of the rolled piece to improve the fatigue strength and service life of the roll. Check the wear and tear of the rolls and guides from time to time.

2. Reverse the injection process of bearing lubricating oil – from the original internal-external to external-internal, so as to reduce the pollution of dust to the bearing.

3. Use ultrasonic technology to inspect and analyze the rolls of hot rolling mills.

Luoyang HTGP is a professional manufacturer of hot rolling mill machines with more than ten years of production experience. If you have any questions about hot rolling steel mills, welcome to consult.