How to Buy Proper Melting Furnaces?

In the forging industry, melting furnaces are widely used and frequently replaced. However, the quality of melting furnaces on the market is uneven, making it difficult to choose. So, how can you buy the right melting furnace? Today, Luoyang Hongteng will give you a detailed introduction to the knowledge about melting furnaces and how to choose a melting furnace.

What Is A Melting Furnace?

A melting furnace is a furnace or electric furnace used to heat iron, steel, or other metals. A furnace heats metal to a temperature that makes it easier to shape it by forging or heats it until it melts into a liquid state before casting it.

Types and Working Principles of Melting Furnaces

There are many types of melting furnaces depending on factors such as heating methods and uses.

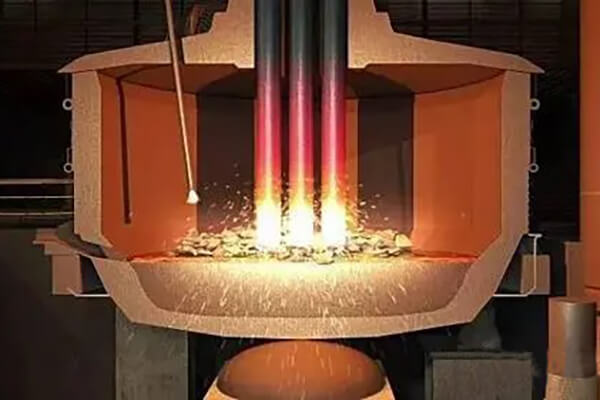

Electric Arc Furnace: An electric arc furnace is a furnace that uses electric arcs to heat and melt substances. It is usually used in metallurgy, steel, non-ferrous metals, and other industries. The method of use is to put the material into the furnace and discharge the electrode into the furnace to generate arc heating until the material melts.

Induction Furnace: An induction furnace is a device that uses an alternating magnetic field to induce the internal current of the material to heat and melt the material. Usually, it is used in metal smelting, casting, quenching, and other industrial fields. The method of use is to put the material into the induction coil to generate an induction current to heat the material until it melts.

Gas Furnace: A gas furnace is a device that uses gas combustion to generate high temperatures and heat and melt materials. Usually used in glass, ceramics, and other industries. The method of use is to introduce gas into the furnace to burn to generate high temperature and put the material into the furnace to heat until it melts.

Vacuum Furnace: A vacuum furnace is a device that heats and melts materials in a vacuum environment. Usually, it is used in industries such as precision alloys and high-purity metals. The method of use is to put the material into a vacuum furnace, remove the air, and heat the material by electric heating or other methods until it melts.

Characteristics of Different Melting Furnaces

Electric arc furnace

1. High thermal efficiency. The heat source is electric energy, and the efficiency can reach more than 65%;

2. Pure. The electric energy is directly input into the energy to avoid the pollution of molten steel caused by fuel combustion;

3. Easy to control. The temperature of the smelting bath is high and easy to control, meeting the requirements of smelting different steel types;

4. Easy to operate. The power input into the molten pool is easy to adjust, so it is easy to realize the automatic heating of the molten pool;

5. Environmental protection. Electric arc furnace steelmaking can consume steel scrap. This is not only a recycling process of iron resources, but also an environmentally friendly technology to deal with pollution.

Induction Furnace

1. Fast melting speed. It takes an average of 30 to 100 minutes for an induction furnace to melt a furnace of steel;

2. Easy to install. Generally, the induction furnace can be used only by connecting water and electricity, and does not require professional and technical personnel to install;

3. Safe operation. The induction furnace has a self-test function, which can detect water temperature, water pressure, overcurrent, overvoltage, and lack of phase faults in real-time;

4. Constant power heating. The power of the induction furnace can be adjusted arbitrarily within the allowable range according to the needs, which is conducive to improving product quality and simplifying the operation of workers;

5. Long service life. The average service life of an induction furnace is more than 10 years.

Gas Furnaces

1. The temperature of the gas furnace is uniform, and the workpiece is heated evenly;

2. The gas furnace has a large loading capacity and high productivity, and is suitable for tempering and preheating various types of parts;

3. The gas furnace lining adopts a full-fiber structure, which improves the thermal insulation performance of the furnace body, saves energy, and reduces production costs;

4. The gas furnace is easy to load and unload, and the operating conditions are good;

5. The gas furnace is equipped with an interlock protection device, which can prevent failures and accidents caused by misoperation;

6. No pollution, good environmental benefits.

Vacuum Furnaces

1. Completely eliminate the oxidation and decarburization of the workpiece surface during the heating process, and obtain a clean surface without a metamorphic layer.

2. No pollution to the environment, no need for three waste treatments.

3. The accuracy of furnace temperature measurement and monitoring is significantly improved. The indicated value of the thermocouple and the temperature of the furnace reach ±1.5°C. However, the temperature difference between different parts of a large number of workpieces in the furnace is relatively large. If the forced circulation of thin gas is used, it can still be controlled within the temperature difference range of ±5°C.

4. The high degree of mechatronics. On the basis of improved temperature measurement and control accuracy, workpiece movement, air pressure adjustment, power adjustment, etc. can be pre-programmed, and quenching and tempering are implemented step by step.

5. The energy consumption is significantly lower than that of the salt bath furnace. The modern and advanced vacuum furnace heating chamber adopts heat insulation walls and barriers made of high-quality heat insulation materials, which can highly concentrate the electric heating energy in the heating chamber, and the energy-saving effect is remarkable.

Application Scenarios of Different Melting Furnaces

Electric Arc Furnace

The raw material for the electric arc furnaces is mainly solid scrap steel with alloy material, pig iron for adjusting carbon content, etc., and direct reduced iron or a part of hot metal can also be used. The choice of raw materials is wide. Therefore, except for some ultra-low carbon, most steel types can be smelted.

The electric arc furnaces can not only smelt high-quality steel with low content of phosphorus, sulfur, and oxygen but also can alloy with various elements (including easily oxidized elements such as lead, boron, vanadium, titanium, and rare earth) to produce various high-quality steel and alloy steel.

Induction Furnaces

Induction furnaces are mainly used for smelting and heat preservation of steel, cast iron, copper, aluminum, magnesium, zinc, and other non-ferrous metals and their alloys. In recent years, induction furnaces have not only been widely used in the production of steel and alloys but also developed rapidly in cast iron production, especially in continuous casting and rolling production lines.

Gas Furnaces

The gas furnace is mainly used for quenching, annealing, aging, and heat treatment of various mechanical parts such as high chromium and high manganese steel castings, ductile iron, rolls, steel balls, 45 steel, and stainless steel.

Vacuum Furnace

A vacuum furnace is a device that heats metal in a vacuum environment. The furnace vacuum can reach 133×(10-2~10-4)Pa. The heating system in the furnace can be directly heated by electric resistance furnace wire or can be heated by high-frequency induction. The maximum heating temperature of the vacuum furnace can reach about 3000°C. It is mainly used for ceramic firing, vacuum smelting, degassing and annealing of electric vacuum parts, brazing of metal parts, ceramic-metal sealing, etc.

Summary

Each melting furnace has its own unique advantages and applications. When we buy a melting furnace, we should choose the most suitable one according to our actual situation. The above is the sharing that Luoyang Hongteng brought to you today, and I hope it will be helpful to you.